Turbochargers Fundamentals Explained

Table of ContentsRumored Buzz on TurbochargersWhat Does Turbochargers Do?Turbochargers Can Be Fun For Anyone

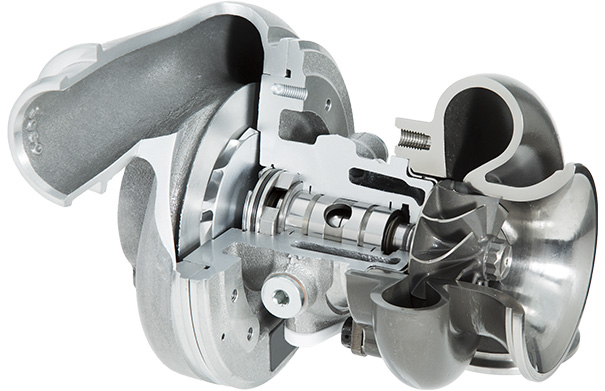

Forced induction gadget for internal combustion engines A turbocharger, colloquially known as a turbo, is a turbine- driven, required induction device that increases an internal combustion engine's effectiveness and power output by requiring additional compressed air into the combustion chamber. This enhancement over a naturally aspirated engine's power output is because the compressor can force more airand proportionately more fuelinto the combustion chamber than atmospheric pressure (and for that matter, ram air intakes) alone - turbochargers.Today, the term "supercharger" is normally used just to mechanically driven forced induction devices. The crucial distinction in between a turbocharger and a traditional supercharger is that a supercharger is mechanically driven by the engine, often through a belt connected to the crankshaft, whereas a turbocharger is powered by a turbine driven by the engine's exhaust gas.

Twincharger describes an engine with both a supercharger and a turbocharger. Producers typically use turbochargers in truck, cars and truck, train, aircraft, and construction-equipment engines. They are most frequently utilized with Otto cycle and Diesel cycle internal combustion engines. Forced induction go back to the late 19th century, when Gottlieb Daimler patented the technique of utilizing a gear-driven pump to require air into an internal combustion engine in 1885.

This patent was for a substance radial engine with an exhaust-driven axial flow turbine and compressor mounted on a common shaft. The very first model was ended up in 1915 with the aim of conquering the power loss experienced by aircraft engines due to the reduced density of air at high altitudes.

Another early patent for turbochargers was looked for in 1916 by French steam turbine innovator Auguste Rateau, for their meant use on the Renault engines used by French fighter planes. Individually, 1917 testing by the American National Advisory Committee for Aeronautics and Sanford Alexander Moss revealed that a turbocharger could make it possible for an engine to prevent any power loss (compared to the power produced at sea level) at an altitude of up to 4,250 m (13,944 feet) above sea level.

The first commercial application of a turbocharger was in 1925, when Alfred Bchi successfully installed turbochargers on ten-cylinder diesel motor, increasing the power output from 1,300 to 1,860 kilowatts (1,750 to 2,500 hp). This engine was utilized by the German Ministry of Transport for 2 big traveler ships called the "Preussen" and "Hansestadt Danzig".

The Turbochargers PDFs

Turbochargers were utilized on numerous airplane engines during The second world war, beginning with the Boeing B-17 Flying Fortress in 1938, which used turbochargers Our site produced by General Electric. Other early turbocharged planes consisted of the B-24 Liberator, P-38 Lightning, P-47 Thunderbolt and the speculative Focke-Wulf Fw 190 models. Auto and truck makers began research study into turbocharged engines throughout the 1950s, however the issues of "turbo lag" and the large size of the turbocharger were not able to be fixed at the time.

Following the 1973 oil crisis and the 1977 Clean Air Act modifications, turbocharging ended up being more typical in autos, as a method to lower fuel usage and exhaust emissions. In contrast to turbochargers, superchargers are mechanically driven by the engine. Belts, chains, shafts, and gears are common techniques description of powering a supercharger, positioning a mechanical load on the engine.

Adiabatic performance is a measure of a compressor's capability to compress air without adding excess heat to that air. Even under perfect conditions, the compression process Visit Website constantly results in raised output temperature; however, more efficient compressors produce less excess heat. Roots superchargers impart substantially more heat to the air than turbochargers.

In practical application the variation between the two can be significant, with turbochargers often producing 15% to 30% more power based solely on the differences in adiabatic effectiveness (however, due to heat transfer from the hot exhaust, significant heating does happen). By comparison, a turbocharger does not position a direct mechanical load on the engine, although turbochargers position exhaust back pressure on engines, increasing pumping losses.

The Ultimate Guide To Turbochargers

Only when the engine reaches sufficient speed does the turbine area start to spool up, or spin fast enough to produce intake pressure above air pressure. A combination of an exhaust-driven turbocharger and an engine-driven supercharger can reduce the weaknesses of both. This technique is called twincharging. In the case of Electro-Motive Diesel's two-stroke engines, the mechanically assisted turbocharger is not particularly a twincharger, as the engine utilizes the mechanical help to charge air only at lower engine speeds and startup.

This differs from a turbocharger that uses the compressor area of the turbo-compressor only during beginning and, as a two-stroke engines can not naturally aspirate, and, according to SAE meanings, a two-stroke engine with a mechanically assisted compressor during idle and low throttle is considered naturally aspirated. In naturally aspirated piston engines, consumption gases are drawn or "pressed" into the engine by air pressure filling the volumetric void triggered by the downward stroke of the piston (which produces a low-pressure location), comparable to drawing liquid using a syringe. turbochargers.